Technical Materials and Manufacturing

Sambar custom knives only uses the best materials and processes available in the production of fine knives. Below is an insight into why I select these along with detail of what goes into making these highly desirable pieces.

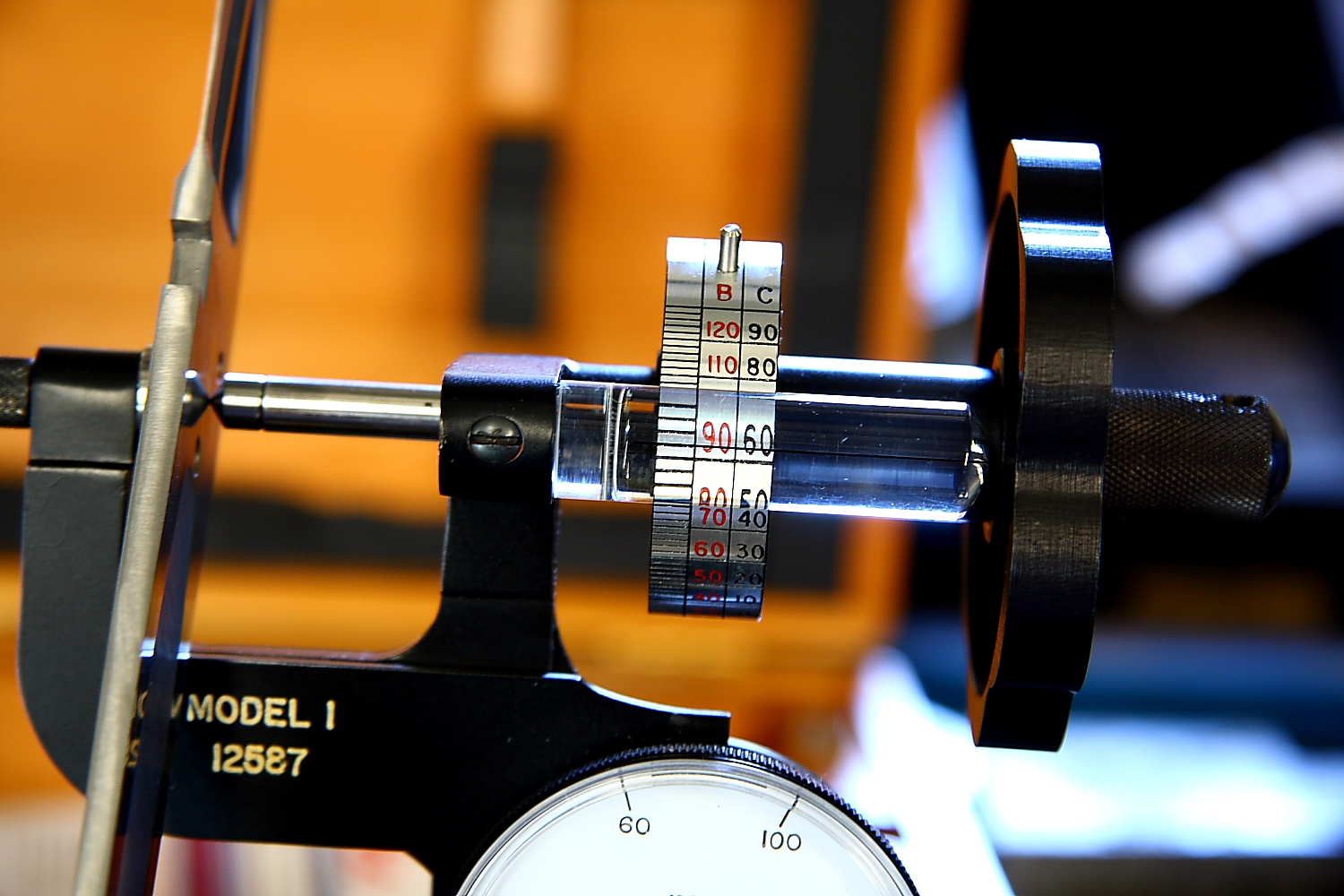

Hardness Testing

All Sambar custom knives undergo a hardness test after our inhouse heat treatment process, shown here is a knife passing this test, consistent 61Rc for ATS 34 steel.

Manufacturing

Materials

Below are the types of steel I use along with the attributes of each.

Toughness & flexability with excellent corrosion resistance and good edge holding.

Good toughness along with good corrosion resistance and edge holding.

Very hard wearing with exceptional edge holding.

Best damascus stainless steel which combines all of the attributes of toughness, edge holding and corrosion resistance along with beautifull appearance all in one package.

-

Table of properties (various steels I use)

Steel (HRc) Edge retention Strength Stain Resistance

440C (59) 4 9 10

ATS34 (60) 6 8 6

S30V (61) 8 8 8

S30V (59) 8 9 8

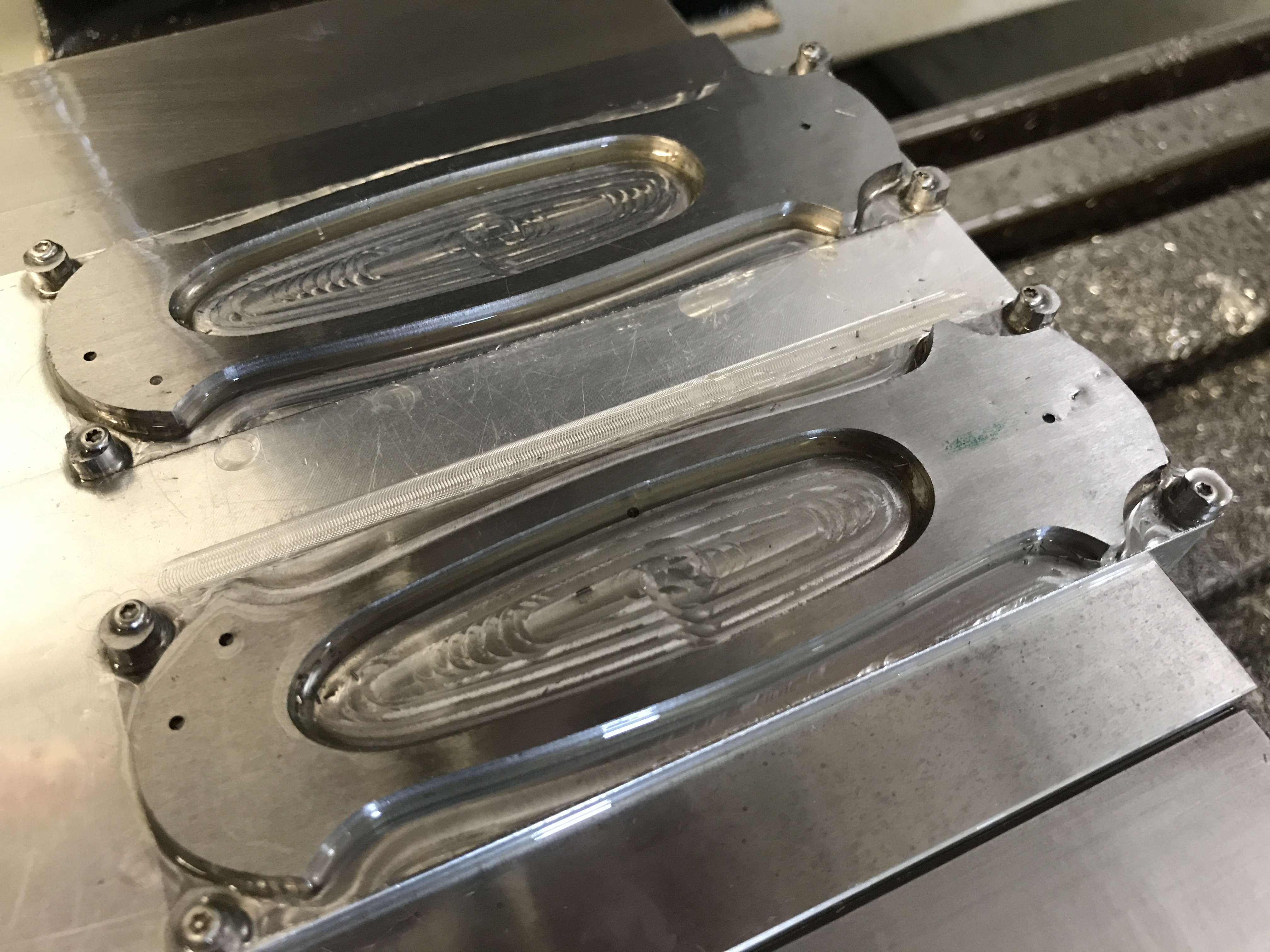

Heat Treatment Processes

All components undergo specific heat treatment processes to increase durability, toughness, wear resistance & edge holding. Blades are scientifically treated in an inert gas computer controlled oven and are given exactly a 59~61 Rockwell C treatment. Moving components in folding knives like pivot bushes, springs, locking backs are given specific hardening processes to ensure longest life with highest wear resistance.

Bolsters and Guards

Stainless Steels of various varieties are employed from 304, 416, to Mosaic Damascuss. These are soldered and rivetted in place on fixed blades and on folding kinves held with torx screws. All folding knives are take down versions meaning the whole knife can be disassembled down to its individual components for easy cleaning and service.

Handle Materials

Desert iron Wood

African Black Wood

Micarta

Ivory and Synthetic Ivory

Sambar Stag

Mother of Pearl

Assembley and Fittment

All are held down with couter sunk bespoke screws and expoxied on fixed blades for added strength.

Sheaths

Made from genuine 3.5mm vegitable oil tanned cow hide, All are hand inlet stiched (stiches below surface) for durability. These are finally died and sealed to give a long lasting durable finish resistant to moisture and stains.

|